PRODUCTION

one-woman businessEvery Woodcabin garment is made by one person: me! The materials are sourced in person and the whole process happens in my little rooftop studio/room, so your clothes don’t have to travel too far before arriving at your doorstep. That also means that with your purchase, you are supporting me and my work directly, without middlemen.

How your clothes are made

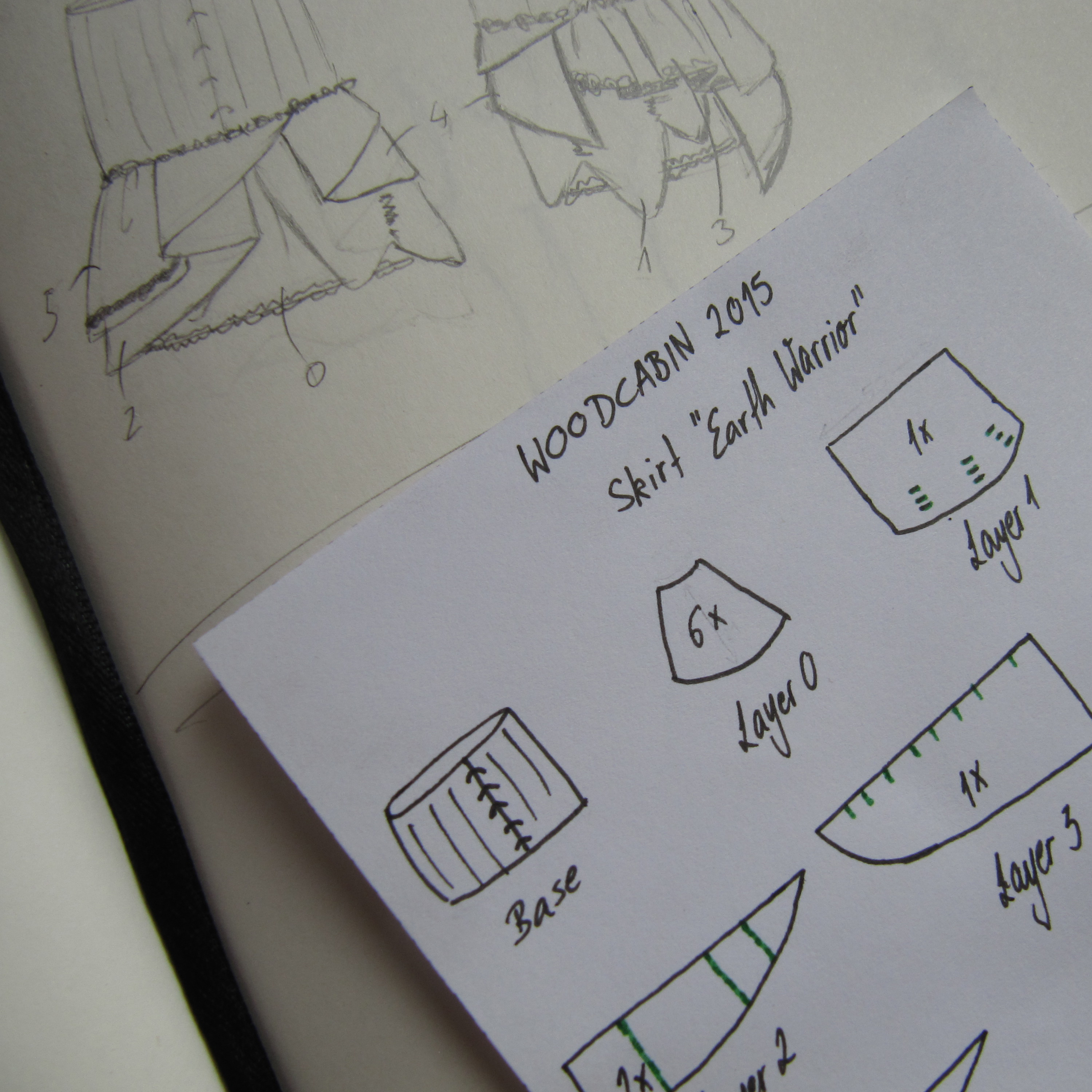

Once the materials are decided on, the design phase happens. These two actually often go hand in hand, where I find a material and immediately have an idea for it, or I have had a design in my mind for a while and finally find a fabric that fits it perfectly. Focussing on singular projects like that means that the resulting garments are all one-of-a-kind or produced in very small batches, avoiding overproduction.

Now the actual act of creation begins. One of Woodcabin’s goals is to leave no fabric waste if possible and that greatly influences patternmaking. Starting in 2022, all existing patterns are being translated to be zero-waste and all new garments will be constructed with zero-waste patterns as well.

When the fabric is cut, it goes straight to the sewing machine on the same table and is sewn by the same person who also made the pattern and sourced the fabrics: me. This production step is the only part where waste is actively being produced since seam allowances and threads have to be cut. However all these scraps are kept to be put to further use, i.e. as as stuffing for pillows, padding for quilts or other small projects.

The new-born garment is finished off with a hand-painted label and off it goes, straight from the sewing table to your doorstep – with a little stop to hang out on etsy for a bit.

Working Orders

Every single step, from sourcing fabric destined for landfill to sending the garment off to you, happens in one place and is completed by one person. I’m making every single Woodcabin piece myself in my little rooftop room, which I like to call my studio. I own two sewing machines, one of which has been pre-owned by at least two other people. Since I’m the only one working for Woodcabin, there is only one machine running at a time, which conserves a lot of energy compared to a big team of seamstresses. Being on my own also means that I get to see 100% of the money Woodcabin earns without having to add win margins for every step like most big companies do. This results in transparent pricing practices, that only include the material price, a living wage, shopkeeping fees and shipping costs.

Woodcabin is working towards building long-term relationships with small local businesses to source sustainable additional materials like thread, buttons, trims etc. Not only will I be looking for environmentally friendly materials and production processes, but also at the labor practices of every business involved in the supply chain to make sure the workers are paid a living wage and are able to work in a safe environment. Until this goal is reached, I will rely on my current stock as much as possible and only buy virgin material if I can’t find what I need second hand. There is no specific time frame for this goal since I can’t plan how long it takes to find suppliers that comply with all my standards and are local small businesses as well, however I will take care to buy sustainable materials, like recycled thread, whenever possible to do the best I can with the means available.